| Sign In | Join Free | My gastesters.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gastesters.com |

|

Brand Name : JIATUO

Model Number : JT-PET

Certification : CE, ISO

Place of Origin : CHINA

MOQ : 1 Set

Price : 8500-9500USD

Payment Terms : L/C, T/T, D/P

Supply Ability : 50set/month

Delivery Time : 30-40days

Packaging Details : Export wooden boxes

Name : PP Strap Making Machine

Raw material : 100% PP polypropylene

Strap Width : 5-19±0.5 mm

Strap Thickness : 0.3-1.2 mm

Screw diameter : 110/120/135 mm

Screw Material : 38CrMoALA

Paper tube size : 200*180 mm

Stretching ratio : 1-10

Line speed : 100-300 m/min

Finished product : PP packing straps

PET PP Strap Making Machine Single Screw PP strapping equipment with automatic screen changer

DESCRIPTION OF PP STRAP MAKING MACHINE:

PP Strap Making Machine/PP belt making machine/PP polypropylene equipment

PP plastic belt equipment is a mechanical equipment used to produce polypropylene (PP) plastic belts, which are widely used in packaging, printing, textile, ceramics, printing, logistics, home appliances and other industries.

## Energy-Efficient and Eco-Friendly

In this era championing sustainable development, this PP strapping production line aligns perfectly with environmental principles. It employs energy-saving, constant-temperature heating systems and motors, effectively reducing energy consumption. By utilising thermal energy to minimise electrical losses, it helps businesses cut production costs. Furthermore, it generates minimal waste during operation, with all by-products being 100% recyclable. This achieves maximum resource utilisation, proving both environmentally responsible and economically sound.

EXTRUSION PARAMETERS TABLE

| Model | PP-2 | PP-4 | PP-6 | PP-8 | PP-10 | PP-12 |

| Raw material | PP polypropylene new material/recycled material | |||||

| Number of tapes | 2 | 4 | 6 | 8 | 10 | 12 |

| Width(mm) | 5-19 | 5-19 | 5-19 | 5-19 | 5-19 | 5-19 |

| Thickness(mm) | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 |

| Line speed(m/min) | ≧260-300 | |||||

| PLC control system | PLC | PLC | PLC | PLC | PLC | PLC |

| Screw Model | 90 | 110 | 125 | 135 | 135 | 135 |

| Reducer model | 200 | 220 | 250 | 280 | 280 | 280 |

| Winding machine | Automatic winding machine /Semi-automatic winding machine | |||||

| Screen Changer | Automatic/Manua | |||||

| Production capacity 24H | 2.5-3T | 6-7T | 8-9T | 10-11T | 12-13T | 13--14T |

Raw materials------

PP strapping equipment can use the following plastic raw materials: 100% recycled material or virgin material to produce strapping.

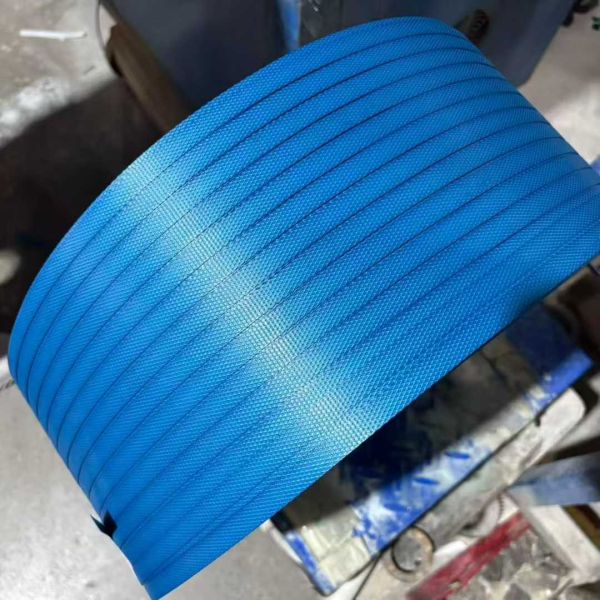

FINISHED PP STRAPPING BELT:

Features:

Good plasticity

Strong breaking force

Bending resistance

Low density

Widely used in many fields, including but not limited to logistics, packaging, transportation, electronic products, hardware, home appliances, clothing, etc.

ABOUT AFTER-SALES

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP belt making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ:

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:Can the PP strapping production equipment be customized according to the factory length?

A:Yes, we can customize the length according to the customer's factory size.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

|

|

PET PP Strap Making Machine Single Screw PP strapping equipment with automatic screen changer Images |